source: www.unimig.com.au

Trying to find the perfect tungsten electrode for your TIG weld can seem like a bit of an adventure. There are lots and kinds out there, with unique pros/cons that may be right up your alley or not so much - it depends what kind you want! We've broken them all down into easy-to learn categories according to Australian Standard Colours so when shopping around online at least one thing will always look familiar...

What’s in a Tungsten and What Do They Do?

Every tungsten is roughly 95%+ pure tungsten (which used to be the only kind of tungsten you could get) with some additional ingredients mixed in for better results in certain areas. Thoriated tungstens were the second type of tungsten that became available, so a lot of the time, they’re used as a reference point when comparing how the other (newer) tungstens perform.

2% Thoriated (red)

These tungstens contain a small amount of thorium mixed in with the pure tungsten. Thoriated tungstens were the first to have an oxide mixed with pure tungsten. They can’t be used for AC (the tungsten just burns back into the cup if you try), but they perform well on DC. In technical terms, the added thorium boosts the electron emission qualities in the tungsten. In simple terms, the added thorium means the tungsten needs a lower amount of heat to start and maintain an arc, which has a bunch of benefits:

• Good arc starts

• A very stable arc

• A high current carrying capacity

• It operates below its melting point, which improves its lifespan significantly

• It doesn’t spit, so there’s less chance of contamination

• It maintains a sharpened point

They used to be the best for any DC TIG welding, but they’re no longer as popular. The problem? They’re radioactive. The risk is minimal, but the problem occurs when the thorium enters the lungs.

While welding with a Thoriated tungsten isn’t dangerous, prepping them can be. Preparing the tungsten with a grinder means that the previously trapped thorium is now out in the air, where it can be dangerous. Unless your contract requires you to use them, it’s best to find an alternative (like Lanthanated).

1.5% Lanthanated (gold)

These tungstens contain a small amount of lanthanum mixed in with the pure tungsten. The added lanthanum in the tungsten gives it a roughly 50% increase in its current carrying capacity (compared to Thoriated).

Note: The current capacity of a tungsten is how many amps it can be run on before it starts to deteriorate.

Lanthanated tungstens also work well on both AC and DC, plus they have:

• One of the best arc starts (especially on DC)

• A very stable arc

• A low burn-off/erosion rate, so they last a long time

• Excellent re-ignition (no sticking on restarts)

• They don’t spit, which means less weld contamination

• They can strike and maintain an arc at low or high amperages

• They can be sharpened to a point (which keeps its shape well), or they can be balled

Lanthanated tungstens also share the same conductivity characteristics as Thoriated tungstens.

Note: These characteristics mean that electricity passes through them with the same amount of ease, and they conduct heat in the same way.

Unlike Thoriated electrodes, they aren’t radioactive, which is why they’re considered the best general-purpose tungsten and a good replacement for Thoriated.

0.8% Zirconiated ( white )

These tungstens contain a small amount of zirconium mixed in with the pure tungsten. They can’t be used for any DC work, but they’re perfect for AC. Why?

• They ball well and retain the shape

• They have an incredibly stable arc

• Zirconium is a strong metal, so it doesn’t split or spit and contaminate the weld

• It handles high amps well (perfect for aluminium)

• Its current carrying capacity is the same as (and sometimes better then) Thoriated

They’re the go-to tungsten for all of your AC welding because that’s what they’re designed for.

Rare Earth (purple)

Rare Earth tungstens have a mix of different oxides added to them, which can vary depending on which brand/where you get them from. UNIMIG’s Rare Earth tungstens are a combination of lanthanum (1.5%), zirconium (0.08%) and yttrium (0.08%). The combination of several oxides together means it works great on AC and DC, plus:

• Great arc starts

• A very stable arc in AC and DC

• One of the longest electrode lifespans, with less re-grinding needed than usual

• Little spitting

The ability to use a smaller diameter tungsten on a job

• Can handle high amperages (even with a smaller tungsten)

Rare Earth tungstens also share the same conductivity characteristics as Thoriated tungstens. Some brands refer to Rare Earth tungstens as ‘Chartreuse’, but they’re the same thing.

2% Ceriated (grey)

These tungstens contain a small amount of cerium mixed in with the pure tungsten. Ceriated works best on DC, though it does still run on AC. It’s the most popular tungsten when it comes to welding thin materials, thanks to some of its unique properties:

• Excellent arc starts at low amps

• It runs best on DC with low current settings

• Good re-ignition

• Great arc stability

Because of the way cerium oxides behave when they’re heated to extreme temperatures, it’s not recommended to use them on high amperage applications.

Higher amps cause the cerium to concentrate at the tip of the tungsten electrode (at the hottest point). That means the rest of the tungsten is empty of its added oxide, rendering any benefits null and void.

On the flip side, because cerium works so well on low amperages, Ceriated tungstens are perfect for use on sheet metal and thin piping or tubing.

Which Tungsten Do You Need?

We’ve ranked each type of tungsten based on their performance in certain conditions and material types, but what do all the dots on our chart actually mean?

Arc Ignition

How easily does the arc start? A good arc ignition will look slightly different depending on how you’re creating it (lift vs high frequency), but it should generally look like a flare of light with a soft ‘puff’ noise. A good arc will come out in a cone shape.

A few factors can contribute to how your arc starts, but if all your machine’s settings are correct, and your tungsten still starts with little light and remains dull or weak-looking, it doesn’t have a good arc ignition.

Tungsten Life

How long does the tungsten last before it needs grinding, or do you need a new one? Tungsten has the highest melting point of any metal on the periodic table, but that doesn’t mean it will last forever.

Every tungsten handles amp rates differently, and the higher the amps, the faster some tungstens lose their tips. There are a few things that will make your tungsten last longer.

One is proper tip preparation: grinding the end of the tungsten to a point or ball, depending on the application.

Two is being careful not to dip them, which is explained below. Both of these are a great way to make the most out of your tungsten.

Arc Stability

Does the arc flicker or blowout? Is it consistent all the way across the weld? Once the arc has started, it should look like a cone-shaped light that remains totally solid. It shouldn’t flicker, or wander, or blow out if it is stable.

Some things can affect this, like using low amps on thick electrodes, or AC, which is more likely to flicker even when stable, and pulse welding will flick in and out as the arc moves between amp ranges. In general, though, your arc should be steady and maintain that cone appearance for the entire weld.

Resistance to Contamination

How easily does the tungsten become contaminated? One of the main ways that a tungsten becomes contaminated is by dipping it. There are two ways you can dip.

The first way is by touching the tungsten itself into the workpiece. Not a lot will stick to the tungsten generally, and your weld pool should be relatively clean anyway, but if your tip has touched the pool, it will cause a blast of oxide and other contaminations.

When you stub your electrode, you might not always lose the tip’s shape, but the next time you weld with it, it’s going to blow all those contaminants into the start of your weld.

The second way to dip your tungsten is by touching your filler metal rod directly onto it. Instead of the rod melting into your weld pool, it is now coating the outside of your electrode. This causes instant contamination of your tungsten, and a lot of the time it’ll cause the arc to wander.

Long term constant use of the same tungsten will also naturally build up contaminants, like discolouration from the gas and oxidisation, even if you’re cleaning it regularly.

If you’ve dipped your tungsten into the weld pool, don’t worry, you aren’t the first, and even seasoned welders slip up sometimes. It can be a bit of a pain, as you’ll need to re-grind it into shape before you can continue to use it.

If you’ve dipped the filler rod directly onto the tungsten, these can still be salvaged and re-ground; you’ll just need to snap the contaminated end off. This is also true of long-term use contamination and discolouring; you can snap the contaminated part off and grind it into shape until it gets too short to use.

Tungstens that are more resistant to contamination will not suffer as much discolouration or have as many contaminants stick to the tungsten if it is dipped and will take longer to ‘dirty’ from extended use.

AC Performance

How well does the tungsten work when used on an alternating current? AC welding is only used when welding aluminium or magnesium alloys, as you can’t use DC for them.

AC means that the current flows both ways, and a cycle is completed when it has flowed one way and then back the other way. This back and forth of the current has different effects on tungstens than DC (direct current) does, and some tungstens are better suited for AC applications.

‘What happens if I use a Thoriated (or any other DC-specific) electrode on AC?’

We asked ourselves the same thing. The answer: you ruin the tungsten.

When the button is pressed (for high frequency), the tungsten fizzles and burns up back into the cup, and there’s no saving it. We definitely don’t recommend trying it, and if you need to weld aluminium, Zirconiated tungstens are the best.

OUR RANGE OF TIG TUNGSTEN ELECTRODES

TUNGSTENS ZIRCONIATED - ALUM WHITE 2.4MM

TUNGSTEN E3 PURPLE TIPPED 2.4MM

TUNGSTENS THORIATED RED 2.4MM SUIT STAINLESS OR MILD STEEL

Related Posts

Reticulated Gas Pipe System

A well-conceived delivery system will reduce operating costs, increases productivity, and enhance safety. Even when the volume of gas consumed is low a well-designed delivery system will enhance cylinder handling safety and ensure maximum gas utilisation. Let's know more about it with the help of Harris Products Group which is the world leader in Gas Distribution Reticulation.

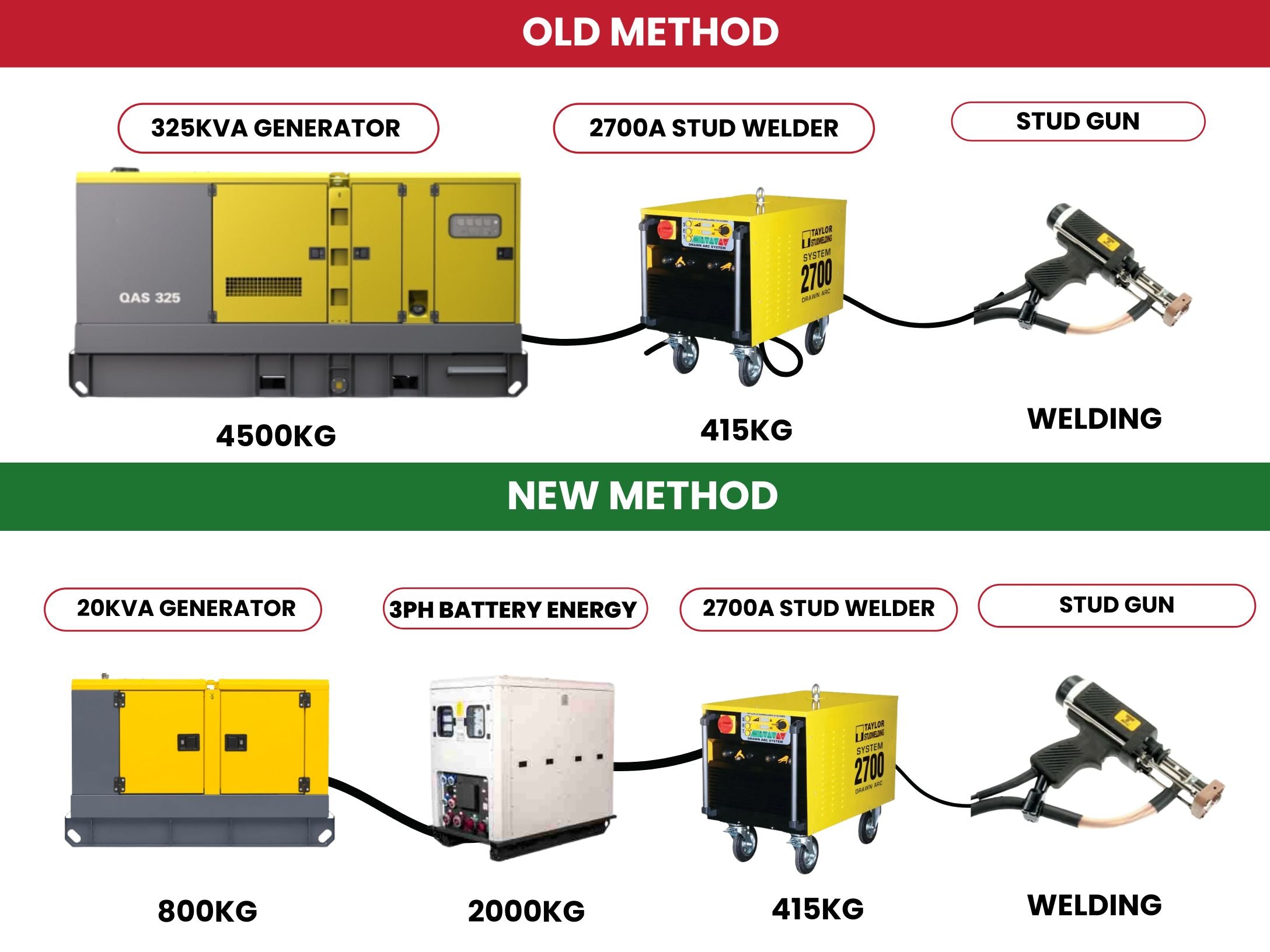

SITE STUD WELDING MADE EASY WITH GENERATORS

Stud welding of shear studs and threaded studs on construction sites, remote locations and site power has been fraught with issues for many years due to the slow excitation of heavy duty generators. With break-through technology used in battery energy storage systems, this enables instant delivery of the required in-rush current at the correct voltage during the short welding process known as stud welding.

Removing Chewing Gum from Concrete: Traditional Methods vs. Cutting-Edge Laser Cleaning

Chewing gum litter is a persistent problem in public spaces. Sidewalks, plazas, and parking lots often become dotted with unsightly black spots where gum has been discarded and ground into the concrete. Traditional cleaning methods, such as pressure washing and chemical solvents, have been the go-to solutions for years. However, technological advancements have introduced an innovative alternative: laser cleaning.